济南聚大邦成化工有限公司

联系人:张总

电话:13583111587

网址:www.jnjdbc.cn

地址:济南市天桥区新材料市场南区7-1-1

精萘品质 “守护者联盟”:解密生产线上的质量保卫战

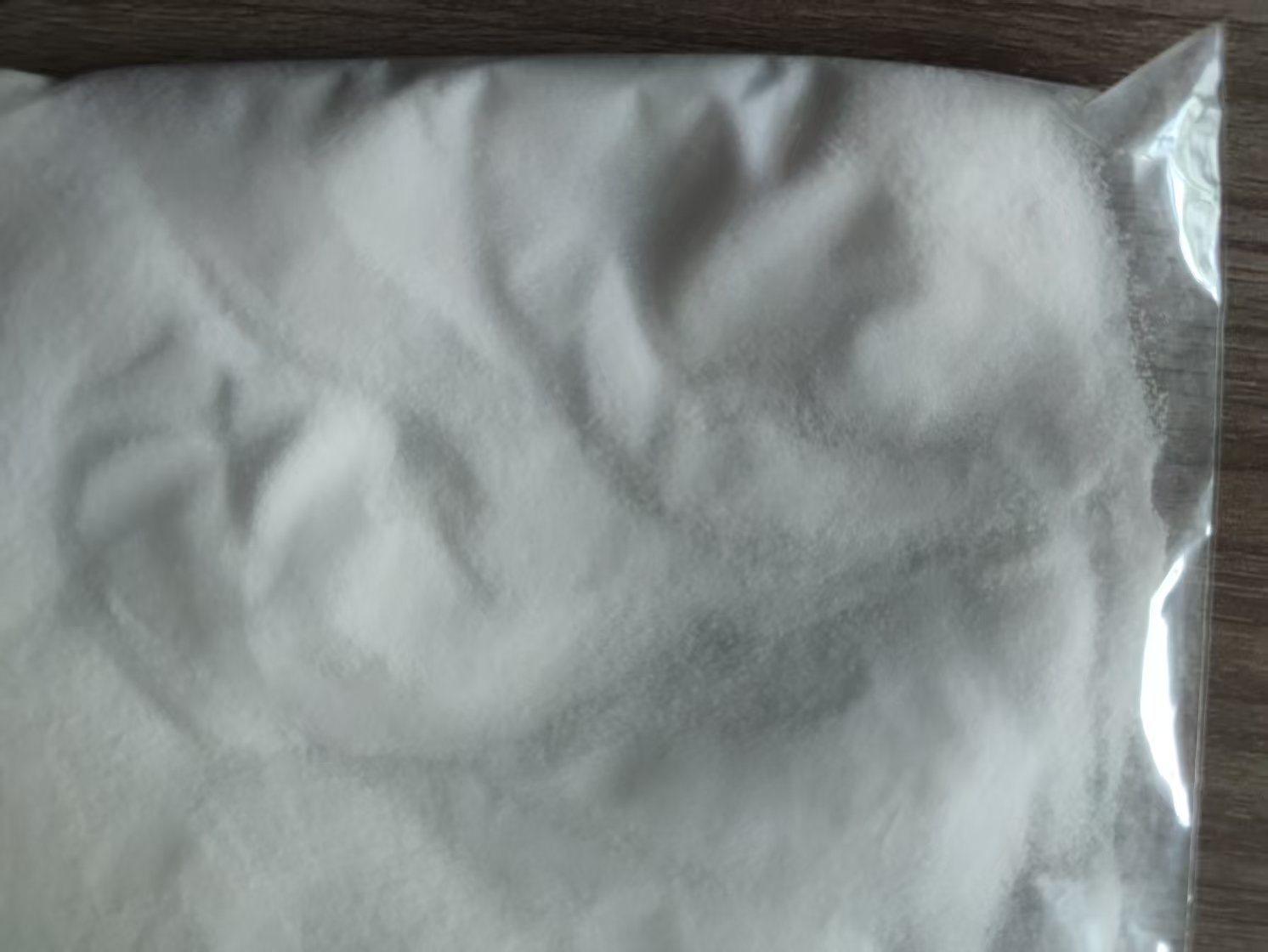

在化工产品的世界里,精萘作为重要的有机原料,其质量直接影响下游产品的性能与应用。对于精萘厂家而言,保障产品质量如同一场持续的 “攻坚战”,需要从原料把控到生产工艺、检测流程等多方面协同作战,才能打造出品质过硬的产品。

In the world of chemical products, refined naphthalene is an important organic raw material, and its quality directly affects the performance and application of downstream products. For naphthalene manufacturers, ensuring product quality is like a continuous "battle" that requires coordinated efforts from raw material control to production processes, testing procedures, and other aspects in order to create high-quality products.

严选原料:筑牢品质的 “第一防线”

Strict selection of raw materials: building the "first line of defense" for quality assurance

优质的原料是生产高品质精萘的基础。精萘厂家在原料采购环节十分严格,对每一批次的粗萘原料都进行详细的质量评估。从原料的来源渠道到供应商资质,都会经过层层筛选,优先选择信誉良好、生产规范的供应商合作。同时,对粗萘的各项指标进行严格检测,如纯度、杂质含量等。纯度高、杂质少的粗萘原料,不仅能提高精萘的生产效率,还能从源头上保障产品质量。例如,若粗萘中含有过多的硫、氮等杂质,在后续生产过程中会影响精萘的纯度和稳定性,因此原料检测不合格坚决不予使用,确保进入生产线的每一份原料都符合高标准。

High quality raw materials are the foundation for producing high-quality refined naphthalene. The refined naphthalene manufacturer is very strict in the raw material procurement process, conducting detailed quality assessments on each batch of crude naphthalene raw materials. From the source channels of raw materials to supplier qualifications, they will go through layers of screening, and priority will be given to selecting suppliers with good reputation and standardized production for cooperation. At the same time, strict testing is conducted on various indicators of crude naphthalene, such as purity and impurity content. High purity and low impurity crude naphthalene raw materials can not only improve the production efficiency of refined naphthalene, but also ensure product quality from the source. For example, if crude naphthalene contains excessive impurities such as sulfur and nitrogen, it will affect the purity and stability of refined naphthalene in the subsequent production process. Therefore, if the raw material testing is not qualified, it will not be used to ensure that every raw material entering the production line meets high standards.

优化工艺:锻造品质的 “核心武器”

Optimizing Process: The 'Core Weapon' of Forging Quality

先进且稳定的生产工艺是精萘质量的关键保障。厂家会不断优化生产流程,采用合适的生产技术,如蒸馏、结晶等工艺,精确控制生产过程中的温度、压力、时间等参数。在蒸馏环节,严格把控蒸馏温度和时间,确保将粗萘中的低沸点和高沸点杂质有效分离;结晶过程中,通过精确控制结晶温度和速度,使精萘形成均匀、规则的晶体结构,提高产品的纯度和外观质量。同时,对生产设备进行定期维护和升级,确保设备运行稳定,避免因设备故障导致产品质量波动。例如,老化的蒸馏塔可能会出现温度控制不精准的问题,影响蒸馏效果,及时更换和维护设备能有效避免此类情况发生,保证精萘生产的稳定性和一致性。

Advanced and stable production processes are the key guarantee for the quality of refined naphthalene. The manufacturer will continuously optimize the production process, adopt appropriate production technologies such as distillation, crystallization, etc., and accurately control parameters such as temperature, pressure, and time during the production process. In the distillation process, strictly control the distillation temperature and time to ensure the effective separation of low boiling point and high boiling point impurities in crude naphthalene; During the crystallization process, by precisely controlling the crystallization temperature and speed, refined naphthalene forms a uniform and regular crystal structure, improving the purity and appearance quality of the product. At the same time, regular maintenance and upgrades are carried out on production equipment to ensure stable operation and avoid product quality fluctuations caused by equipment failures. For example, aging distillation towers may experience inaccurate temperature control, affecting distillation efficiency. Timely replacement and maintenance of equipment can effectively avoid such situations and ensure the stability and consistency of refined naphthalene production.

严格检测:把控品质的 “终极关卡”

Strict testing: the ultimate level of quality control

为确保精萘质量达标,厂家建立了完善的检测体系。从生产过程中的中间产品检测,到成品出厂前的全面检验,每一个环节都不放过。在生产过程中,定期对中间产品进行抽样检测,及时发现生产过程中的质量问题并进行调整,防止问题产品流入下一道工序。成品检测则更加严格,依据相关标准和规范,对精萘的纯度、结晶点、灰分、硫含量等关键指标进行精确检测。采用先进的检测设备,如气相色谱仪、差示扫描量热仪等,确保检测结果的准确性和可靠性。只有各项指标都符合标准的产品,才会被允许出厂销售。此外,厂家还会对检测数据进行详细记录和分析,通过数据的变化趋势,总结生产过程中的经验教训,持续改进生产工艺和质量控制措施。

To ensure the quality of refined naphthalene meets the standard, the manufacturer has established a comprehensive testing system. From intermediate product inspection during the production process to comprehensive inspection before the finished product leaves the factory, every link is not missed. During the production process, regular sampling and testing of intermediate products are conducted to promptly identify quality issues and make adjustments to prevent problematic products from flowing into the next process. Finished product testing is even stricter, with precise testing of key indicators such as purity, crystallization point, ash content, and sulfur content of refined naphthalene based on relevant standards and specifications. Advanced detection equipment such as gas chromatography and differential scanning calorimetry are used to ensure the accuracy and reliability of the detection results. Only products that meet the standards in all aspects will be allowed to leave the factory for sale. In addition, the manufacturer will also record and analyze the testing data in detail, summarize the experience and lessons learned in the production process through the trend of data changes, and continuously improve the production process and quality control measures.

规范管理:护航品质的 “隐形盾牌”

Standardized Management: The 'Invisible Shield' of Escort Quality

除了技术层面的保障,规范的企业管理也是精萘质量保证的重要因素。厂家会制定严格的质量管理体系和操作规范,要求员工严格遵守。对员工进行定期的培训和考核,提高员工的质量意识和操作技能,确保每一个生产环节都能按照标准执行。在仓储管理方面,对精萘产品进行妥善储存,控制仓库的温度、湿度等环境条件,防止产品受潮、氧化等,影响质量。同时,建立产品追溯体系,一旦出现质量问题,能够快速追溯到生产的各个环节,及时查明原因并采取措施解决,保障客户的利益和企业的信誉。

In addition to technical support, standardized enterprise management is also an important factor in ensuring the quality of refined naphthalene. Manufacturers will establish strict quality management systems and operating standards, requiring employees to strictly comply. Regularly train and assess employees to improve their quality awareness and operational skills, ensuring that every production process is executed according to standards. In terms of warehouse management, the refined naphthalene products are stored properly, and the temperature, humidity, and other environmental conditions of the warehouse are controlled to prevent the products from being affected by moisture, oxidation, and other factors that may affect their quality. At the same time, establish a product traceability system that can quickly trace back to various stages of production in case of quality problems, identify the causes in a timely manner, and take measures to solve them, ensuring the interests of customers and the reputation of the enterprise.

精萘厂家通过严选原料、优化工艺、严格检测和规范管理等一系列措施,构建起全方位的质量保证体系。每一个环节都如同 “守护者联盟” 的成员,各司其职,共同为精萘的品质保驾护航,为下游企业提供可靠、优质的产品,在市场竞争中赢得口碑与信赖。

The refined naphthalene manufacturer has established a comprehensive quality assurance system through a series of measures such as strict selection of raw materials, optimization of processes, strict testing, and standardized management. Each link is like a member of the "Guardian Alliance", each performing their own duties, jointly safeguarding the quality of refined naphthalene, providing reliable and high-quality products for downstream enterprises, and winning reputation and trust in market competition.

本文由精萘厂家友情奉献.更多有关的知识请点击:http://www.jnjdbc.cn我们将会对您提出的疑问进行详细的解答,欢迎您登录网站留言.

This article is a friendly contribution from the manufacturer of refined naphthalene For more information, please click: http://www.jnjdbc.cn We will provide detailed answers to your questions. You are welcome to log in to our website and leave a me

推荐阅读/ Recommended reading

- 精萘接触中皮肤防护的核心要点与应对策略 2025-07-07

- 精萘结晶:探寻从液态到固态的 “华丽变身” 密码 2025-07-03

- 精萘品质 “守护者联盟”:解密生产线上的质量保卫战 2025-07-01

- 精萘 “生物分解之谜”:微生物能攻克这个难题吗? 2025-06-25

精萘作为一种常见的化工原料,其性质与应用一直受到广泛关注。了解其毒性特点和合理使用范围,对于安全操作和环境保护具有重要意义。 As a common chemical ra...