济南聚大邦成化工有限公司

联系人:张总

电话:13583111587

网址:www.jnjdbc.cn

地址:济南市天桥区新材料市场南区7-1-1

精萘在橡胶工业中的核心作用:从硫化促进到性能优化的多维解析

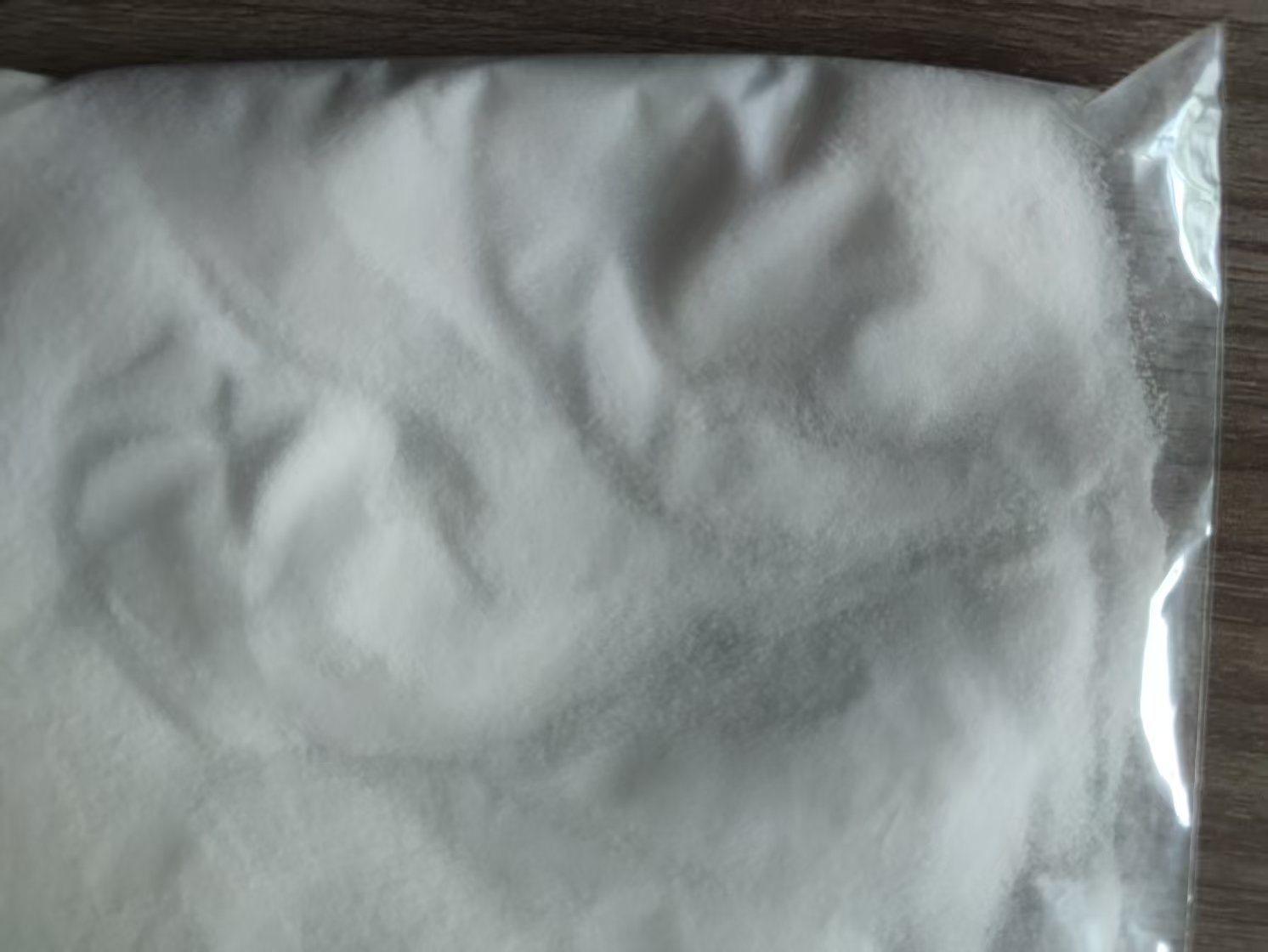

精萘作为橡胶工业的关键原料,其应用贯穿了从基础硫化到高端性能优化的全流程。作为白色片状结晶的稠环芳烃化合物,精萘通过独特的化学特性,在橡胶加工中扮演着不可替代的角色。

As a key raw material in the rubber industry, refined naphthalene is applied throughout the entire process from basic vulcanization to high-end performance optimization. As a white crystalline polycyclic aromatic compound, naphthalene plays an irreplaceable role in rubber processing due to its unique chemical properties.

一、硫化反应的加速引擎

1、 Acceleration engine for sulfurization reaction

在橡胶硫化过程中,精萘作为促进剂的核心成分,能够显著缩短硫化周期。其分子结构中的芳香环体系可与硫磺形成络合物,降低硫化反应的活化能。实验数据显示,添加精萘衍生物的胶料,硫化时间可缩短30%-50%,同时硫化温度降低10-15℃。这种效率提升不仅减少能源消耗,更通过缩短高温暴露时间,抑制了橡胶大分子的热氧降解,使硫化胶的交联密度均匀性提升20%以上。

During the rubber vulcanization process, naphthalene, as the core component of the accelerator, can significantly shorten the vulcanization cycle. The aromatic ring system in its molecular structure can form complexes with sulfur, reducing the activation energy of sulfurization reactions. Experimental data shows that adding naphthalene derivatives to the rubber compound can shorten the vulcanization time by 30% -50%, while reducing the vulcanization temperature by 10-15 ℃. This efficiency improvement not only reduces energy consumption, but also suppresses the thermal oxidative degradation of rubber macromolecules by shortening the exposure time to high temperatures, resulting in a more than 20% increase in the uniformity of crosslinking density of vulcanized rubber.

二、交联网络的构筑师

2、 Constructor of cross-linked networks

精萘通过参与硫化反应,直接影响橡胶的交联结构。在天然橡胶中,其可促进多硫交联键向单硫交联键转化,使交联点分布更趋均匀。这种结构优化带来双重效益:拉伸强度提升15%-25%,同时压缩永久变形降低30%以上。对于丁苯橡胶等合成胶种,精萘的加入能改善炭黑分散性,使填料-聚合物界面结合强度提高,动态疲劳寿命延长2-3倍。

Naphthalene directly affects the cross-linking structure of rubber by participating in vulcanization reactions. In natural rubber, it can promote the conversion of polysulfide crosslinking bonds to monosulfide crosslinking bonds, making the distribution of crosslinking points more uniform. This structural optimization brings dual benefits: an increase in tensile strength of 15% -25%, while reducing compression permanent deformation by more than 30%. For synthetic rubber such as styrene butadiene rubber, the addition of refined naphthalene can improve the dispersion of carbon black, increase the bonding strength between filler polymer interface, and prolong the dynamic fatigue life by 2-3 times.

三、耐老化性能的守护者

3、 Guardian of aging resistance performance

橡胶制品在长期使用中面临的热氧老化问题,可通过精萘的抗氧化机制得到有效缓解。其分子中的共轭大π键可捕获过氧化自由基,中断老化链式反应。在耐热测试中,添加精萘体系的橡胶制品,热老化系数(70℃×72h)保持在0.85以上,相较于未添加体系提升40%。这种保护作用在户外制品中尤为重要,可延缓龟裂发生时间,延长使用寿命。

The thermal oxidative aging problem faced by rubber products during long-term use can be effectively alleviated through the antioxidant mechanism of refined naphthalene. The conjugated large π bonds in its molecule can capture peroxidation radicals and interrupt the aging chain reaction. In the heat resistance test, rubber products with the addition of refined naphthalene system maintained a thermal aging coefficient (70 ℃× 72h) above 0.85, which was 40% higher than that without the addition of the system. This protective effect is particularly important in outdoor products, as it can delay the occurrence of cracking and extend the service life.

四、加工性能的调控枢纽

4、 Control hub for processing performance

在混炼工艺中,精萘作为软化剂可调节胶料门尼粘度。其独特的分子结构使其在橡胶基体中形成微晶分散相,既保持胶料挺性,又降低生热。这种双重作用使挤出膨胀率降低15%,压延表面光洁度提升一个等级。对于高填充体系,精萘的加入可改善填料浸润性,使混炼能耗下降20%左右。

In the mixing process, refined naphthalene can be used as a softener to adjust the Mooney viscosity of the rubber material. Its unique molecular structure enables it to form a microcrystalline dispersed phase in the rubber matrix, which not only maintains the stiffness of the rubber material but also reduces heat generation. This dual effect reduces the extrusion expansion rate by 15% and improves the surface smoothness of the rolled material by one level. For high filling systems, the addition of refined naphthalene can improve the wettability of fillers and reduce mixing energy consumption by about 20%.

五、环保配方的协同伙伴

5、 Collaborative partners for environmentally friendly formulas

随着绿色橡胶技术的发展,精萘正与新型助剂形成协同体系。在与生物基增塑剂并用时,其可促进相容性,使力学性能衰减控制在5%以内。在无亚硝胺体系开发中,精萘与次磺酰胺类促进剂复配,既保持硫化效率,又使挥发性有机物排放降低60%。这种兼容性使其在食品级、医疗级橡胶制品中保持应用潜力。

With the development of green rubber technology, refined naphthalene is forming a synergistic system with new additives. When used in combination with bio based plasticizers, it can promote compatibility and control mechanical property degradation within 5%. In the development of nitrosamine free systems, the combination of naphthalene and sulfonamide accelerators not only maintains sulfurization efficiency but also reduces volatile organic compound emissions by 60%. This compatibility enables it to maintain its potential for application in food grade and medical grade rubber products.

六、特种橡胶的性能突破口

6、 Breakthrough in the Performance of Special Rubber

在氟橡胶、硅橡胶等特种橡胶领域,精萘的应用正在开辟新路径。通过表面接枝改性,其可提升氟橡胶的硫化返原抑制能力,使高温(200℃)压缩永久变形降低至35%以下。在硅橡胶中,精萘衍生物作为结构控制剂,可抑制分子链重排,使拉伸断裂能提升2倍以上,拓展了在航空航天密封件领域的应用。

In the field of special rubber such as fluororubber and silicone rubber, the application of refined naphthalene is opening up new paths. By surface grafting modification, it can enhance the vulcanization reversion inhibition ability of fluororubber, reducing the permanent deformation under high temperature (200 ℃) compression to below 35%. In silicone rubber, naphthalene derivatives serve as structural control agents, which can inhibit molecular chain rearrangement and increase tensile fracture energy by more than 2 times, expanding their applications in the field of aerospace seals.

精萘在橡胶工业中的价值,体现在对硫化动力学、交联结构、耐久性能的精准调控能力。随着分析技术的发展,其作用机制正被深入解析,如通过原位红外光谱观察到的硫化中间态稳定效应,为配方设计提供理论支撑。未来,在高性能弹性体开发中,精萘及其衍生物仍将是实现综合性能突破的关键原料之一。

The value of refined naphthalene in the rubber industry is reflected in its precise control over vulcanization kinetics, cross-linking structure, and durability performance. With the development of analytical techniques, its mechanism of action is being deeply analyzed, such as the sulfurization intermediate state stabilization effect observed through in-situ infrared spectroscopy, which provides theoretical support for formulation design. In the future, in the development of high-performance elastomers, refined naphthalene and its derivatives will still be one of the key raw materials for achieving comprehensive performance breakthroughs.

本文由精萘厂家友情奉献.更多有关的知识请点击:http://www.jnjdbc.cn我们将会对您提出的疑问进行详细的解答,欢迎您登录网站留言.

This article is a friendly contribution from the manufacturer of refined naphthalene For more information, please click: http://www.jnjdbc.cn We will provide detailed answers to your questions. You are welcome to log in to our website and leave a me

推荐阅读/ Recommended reading

- 精萘接触中皮肤防护的核心要点与应对策略 2025-07-07

- 精萘结晶:探寻从液态到固态的 “华丽变身” 密码 2025-07-03

- 精萘品质 “守护者联盟”:解密生产线上的质量保卫战 2025-07-01

- 精萘 “生物分解之谜”:微生物能攻克这个难题吗? 2025-06-25

精萘作为一种常见的化工原料,其性质与应用一直受到广泛关注。了解其毒性特点和合理使用范围,对于安全操作和环境保护具有重要意义。 As a common chemical ra...